Bioconjugation, what is it all about?

A common reaction pathway is the formation of a thioether bond between an anti-Troponin-I (TnI) monoclonal antibody (AB), and the system enzyme of choice (such as alkaline phosphatase ALP). A common approach to this is to introduce a maleimide function onto the ALP by replacing the endogenous primary amine functions (typically associated with lysine residue side chains) using compounds such as Succinimidyl-4-(N-maleimidomethyl) cyclohexane-1-carboxylate (SMCC). In parallel, the biochemist will then introduce its reactive counterpart on the AB using reagents such as 2imminothiolane (or Traut’s reagent). The activated biochemicals are then combined in a predetermined ratio, pH, Time, Conc, Temp to yield a conjugated product. Careful consideration needs to be put into the molar reaction ratios of the two components in order to achieve the desired performance. At the end of the conjugation period, residual reactive groups are quenched/capped with small molecules to prevent further reactivity.

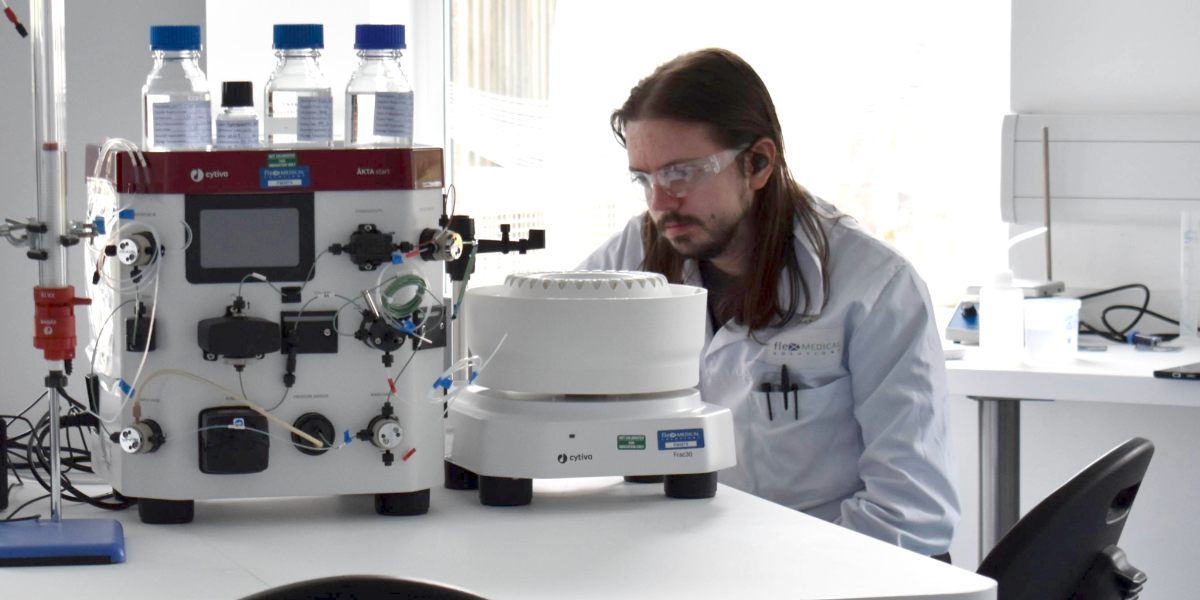

The crude conjugate then needs to go through purification in order to remove unreacted AB and ALP which cause major performance problems in the resultant immunoassay. This is performed by a process called size exclusion gel chromatography (SEC), where by the molecules are fractionated/separated based on molecular mass (weight). The conjugate (sometimes a polymer of predefined size) is eluted first, followed by and unreacted materials (AB and ALP), small molecules are eluted last.

The conjugate is identified in the fractions using spectrophotometry, pooled and finally characterized in the assay to determine its performance.

FMS use Bioconjugation routinely for the development of surface functionalities for electrochemical biosensors, as well as enzyme conjugates for the development of their enzyme enhanced high sensitivity electrochemical immunoassays.